Grounding and Bonding of cable trays

Grounding and Bonding are often associated together but on reality they represent two different concepts .

Grounding is the connection of non current carrying metal parts of equipment to the system's grounded conductor , the grounding electrode conductor , or both at the service equipment .

Bonding is the permanent joining of Metallic parts to form an electrically conductive path .

According to the national electrical code (NEC) , cable trays can be grounded through three ways :

1) using a single EGC conductor in the cable tray .

2) using an EGC conductor for each multiconductor cable layed in the cable tray .

3) The cable tray itself can be used as the EGC and bonding jumpers are used at all splice points to ensure continuity .

Usually , the cable tray is used as an EGC and also a separate EGC cable is placed in the cable .

In case of installing an EGC conductor on the cable tray , it should be clamped at each cable tray section by using grounding clamps for two reasons :

- providing electrical continuity between all sections of cable tray .

- protecting the EGC conductor from being thrown out of the cable tray by the magnetic forces that arises during fault current conditions .

in a moist environment where aluminium cable trays are used , a bare copper EGC conductor should not be placed in the aluminium tray to avoid galvanic corrosion and in this case , an insulated EGC conductor can be used but its insulation should be removed at bonding connections to the cable tray .

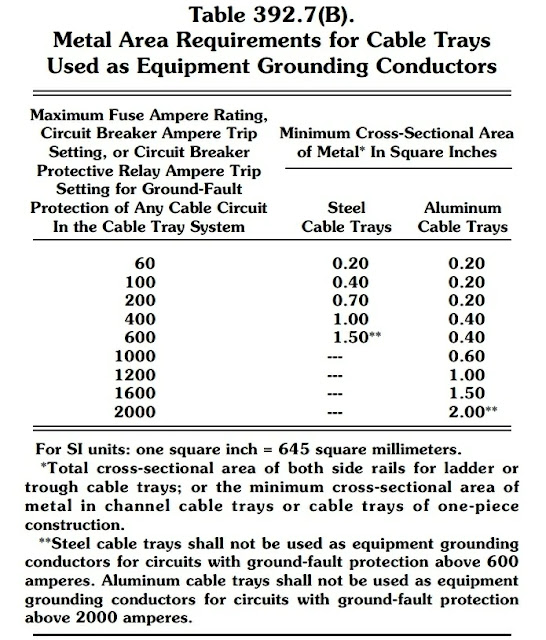

Metal Area Requirements for cable trays used as Equipment Grounding Conductors

The values shown in the first column in table 392.7(B) NEC are the actual trip settings of the circuit breaker not the maximum trip settings which are the same as the frame size of the breaker in many cases .

If the ampere rating of the cable tray is not sufficient for the protective device to be used ,the cable tray can not be used as an EGC and in this case a separate EGC conductor should be placed in the cable tray .

Minimum size of equipment grounding conductors for grounding cable trays (according to NEC)

Bonding jumpers for cable tray bonding

Types of bonding jumpers

- Insulated bonding jumpers

- Bare bonding jumpers

- Braided bonding jumpers

It is not necessary to use bonding jumpers at standard splice plates because its bolted connections provide adequate bonding .

It is important to install two bonding jumpers from both side rails of the cable tray section to the ground bus at switchgear or MCC .