What is cable tray ?

Types of cable trays

- 1) Perforated cable tray

- 2) Ladder cable tray

- 3) Ventilated trough cable tray

- 4) Solid bottom cable tray

- 5) Wire mesh cable tray

- 6) Single rail cable tray

- 7) Channel cable tray

1) Perforated cable tray

- This type of cable trays consists of single metal sheets with side rails, each sheet has holes or openings at bottom which provide good ventilation for cables and allow cables to be fastened to tray by using cable ties .

- It is mainly used for medium heat generating power and control cables.

2) Ladder cable trays

- It gets its name from its ladder like structure .

- It is mainly used for large power cables but it can be used for other cable types.

- It is a prefabricated metal structure made up of two longitudinal side rails connected by individual transverse rungs that are placed at regular intervals , typically at a distance 9 inch from each other .

- The rungs are designed to support the cables by fastening the cables to the rungs using cable cleats.

- It allows for maximum possible air circulation which makes it suitable for cables prone to overheating .

- Cables can enter or exit from the top or the bottom of the ladder between any two rungs .

- It provides easy access to cables installed on it for making inspection or future modifications .

- Its structure prevents moisure and dust accumulation.

- It is generally used in applications with intermediate to long support spans , 12 feet to 30 feet.

3) Ventilated trough cable tray

- It has openings at the bottom that allows for air circulation and water to drain and through these openings small diameter cables can be inserted or taken out of the tray .

- It is used to support small diameter control and multiconductor instrumentation cables.

4) Solid bottom cable tray

- As the name suggests , this type has a solid bottom so it provides maximum protection to cables from bad weather conditions like wing , rain and strong sunlight and also protects cables from any chemicals or other corrosive.

- It can provide protection against radio frequency interference and electromagnetic effects .

- Unlike ladder and ventilated trough cable trays , it can collect and retain moisure and dirt .

- These trays can result in heat built up where cables are packed closed together and are prone to heating .

- Solid bottom steel cable trays with solid covers and wrap around cover clamps can be used to provide EMI/RFI shielding protection for sensitive circuits .

- It is preferred to use this type for supporting large number of small diameter control and multiconductor instrumentation cables.

- It is used for minimal heat generating electrical or telecommunication applications .

|

| Solid bottom steel cable trays |

5) Wire mesh cable trays (Basket trays)

- It is one of the most open structure cable trays so it allows for maximum air flow from all sides and this type is ideal for supporting cables that are prone to overheating .

- It is mainly used for supporting low voltage , telecommunication and fibre optic cables

6) Single rail cable tray

- It is similar to ladder tray except that the longitudinal rail runs through the center of the horizental rungs .

- It is the fastest tray system to install .

- This type of cable trays is suitable for supporting cables that are prone to overheating and also suitable for use in situations where quick access to cables is needed .

- As this type has an open structure , so it makes cables vulnerable to environmental corrosion and it doesn't provide mechanical protection for cables.

7) Channel cable trays

- Channel cable trays is a prefabricated steel structure consists of one piece channel section with width up to 4 inch.

- cable channel can be used very effectively to support cable drops from the cable tray run to the equipment or device being serviced and is ideal for cable tray runs involving a small number of cables and the cable channel or cables are subjected to some degree of vibration.

- Cable channel can also be used to support push buttons, field mounted instrumentation devices, etc.

- Small diameter cables can exit ventilated cable channel through the bottom ventilation holes, out the top or through the end.

Material and finish of cable trays

- 1) Electrogalvanized steel cable trays

- 2) Pre-galvanized steel cable trays

- 3) Hot dip galvanized steel cable trays

- 4) Aluminium cable tray

- 5) stainless steel cable tray

- 6) fiberglass cable tray

1) Electrogalvanized steel cable tray

This type of cable trays are fabricated by depositing a zinc coating on the surface of the fabricated steel through electrolysis from a bath of zinc salts .

The bath used contains acidic or alkaline zink and the anodes are zink while cathodes are the parts of steel to be coated

After being coated the parts are chromated to increase their protection ability .

This type is only suitable for indoor use in dry areas .

2) Pre-galvanized steel cable tray

3) Hot dip galvanized steel cable tray

4) Aluminium cable tray

5) Stainless steel cable tray

Non metallic cable trays

6) Fiberglass cable trays (FRP trays)

FRP : Fiberglass Reinforced Polyester

Characteristics:

- a fiberglass tray is lightweight , on average 15% to 20% that of steel cable tray .

- It has high strength to weight ratio .

- it has high corrosion resistance

- it has low thermal conductivity and is non-conductive .

- It is fire retardant and can be easily installed .

- it is transparent to radio waves , microwaves and other electromagnetic frequencies

- The coefficient of thermal expansion of fiberglass is marginally less than steel and aluminum.

- FRP has excellent mechanical properties at low temperatures .

- it is mainly used in power plants, paper plants ,chemical plants ,offshore platforms ,effluent treatment plants ,refineries.

Types of return flange of cable tray

- Straight

- Return Flange Inside

- Return Flange Outside

- C-Type Inside

- C-Type Outside

Cable tray size selection

Width

The width of cable tray shall be determined based on the sum of overall diameters of all cables intended to be installed inside the tray in addition to spaces between cables and the width standard values are :

50,100,150,200,250,300,400,600,700,900 mm

HEIGHT

The side height of cable tray is choosen based on the largest overall diameter of all cables intended to be placed on the tray and height's standard values are : 50,75,100,25 mmTHICKNESS

The cable trays thickness is choosen based on the sum of weights of all cables intended to be installed inside the tray and the weight of the tray itself .Cable tray support types

- 1) Trapeze system (single or multi-tier)

- 2) Hanger Rod clamps support

- 3) Centre hung support

- 4) Wall and cantilever support brackets

- 5) Underfloor and toproof support

- 6) Vertical support

- 7) Overhead hangers

It is similar to direct rod suspension but instead of clamp it uses steel channel (called C channel) or strut .

A threaded rod and clamps are used for tray suspension

It uses a rod that is installed at the center of the tray .

Wall support brackets are an effective way of fixing any horizontal or vertical cable tray or ladder to a vertical support .

These cantilever brackets can be welded or bolted type .

7) Overhead hangers

Cable tray fittings and accessories

1) Elbow / Bend

2) Tee Connection

3) Reducer

straight reducer

Left hand reducer : when viewed from the wide end , it has a straight side from the left .

right hand reducer : when viewed from the wide end , it has a straight side from the right

4) Cross connection

5) Riser Bend

Types of riser bend :Internal Riser : it is used for changing the direction of the cable tray from a lower level to the upper level .

External Riser : it is used for changing the direction of the cable tray from the upper level to the lower level .

|

| internal and external riser |

|

| Cable tray fitting and accessories |

6) Connectors / splice plates / couplers

- straight connectors

- angle connectors

- adjustable connectors

- Horizontal adjustable connector : it adapts to changes in direction in a horizental plane .

- Vertical adjustable connector : it adapts to changes in direction in a vertical plane

|

| Horizontal adjustable connector |

|

| Vertical adjustable connector |

7) Cable Tray Cover

the cover protect the cables inside the cable tray from mechanical damage , heavy accumulation of dust and direct sunlight .

it also isolates cables from fires and radio frequency from interference.

Types of cover clamps :

Cable trays are used with a cover in outdoor applications and in mechanical rooms

8) Fish plate

9) End Plate

10) Dividers / barrier strips

divider is a fitting that is installed inside the cable tray to physically separate different types or groups of cables within the same tray .

Barrier strips are also used to separate cable systems above and below 600 volts installed in the same cable tray as per NEC 392.6(F).

11) Flexible expansion coupler

it is a fitting that is installed between two cable trays or ladders across the expansion joints of the building structure for the following reasons :

12) Hold down clamps and clips

They are used for fixing cable ladders to heavy duty trapeze hangers , cantilever arms and channels .

|

| Hold down clamps |

|

| Hold down clips |

13) Dtop-out plate

It is a fitting that is installed in cable ladders to support the cables as they exit the ladder down between the rungs .

Drop-out plates can be located either on the side or at the bottom of cable ladder .

14) Tray to box splice plate

It is used to attach the end of cable tray to a distribution box or control panel .

15) Roofing Bolts

16) Threaded rod

17) Support Brackets

18) protection strip

19) Step down splice plate

20) offset reducing connector

It is used for the installation of junction box in cable trays.

Grounding and Bonding of cable trays

Grounding and Bonding are often associated together but on reality they represent two different concepts .

Grounding is the connection of non current carrying metal parts of equipment to the system's grounded conductor , the grounding electrode conductor , or both at the service equipment .

Bonding is the permanent joining of Metallic parts to form an electrically conductive path .

According to the national electrical code (NEC) , cable trays can be grounded through three ways :

1) using a single EGC conductor in the cable tray .

2) using an EGC conductor for each multiconductor cable layed in the cable tray .

3) The cable tray itself can be used as the EGC and bonding jumpers are used at all splice points to ensure continuity .

Usually , the cable tray is used as an EGC and also a separate EGC cable is placed in the cable .

In case of installing an EGC conductor on the cable tray , it should be clamped at each cable tray section by using grounding clamps for two reasons :

- providing electrical continuity between all sections of cable tray .

- protecting the EGC conductor from being thrown out of the cable tray by the magnetic forces that arises during fault current conditions .

in a moist environment where aluminium cable trays are used , a bare copper EGC conductor should not be placed in the aluminium tray to avoid galvanic corrosion and in this case , an insulated EGC conductor can be used but its insulation should be removed at bonding connections to the cable tray .

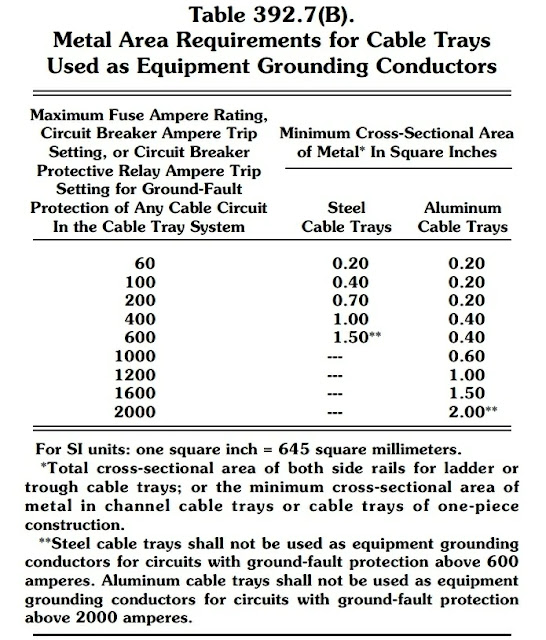

The values shown in the first column in table 392.7(B) NEC are the actual trip settings of the circuit breaker not the maximum trip settings which are the same as the frame size of the breaker in many cases .

If the ampere rating of the cable tray is not sufficient for the protective device to be used ,the cable tray can not be used as an EGC and in this case a separate EGC conductor should be placed in the cable tray .

Minimum size of equipment grounding conductors for grounding cable trays (according to NEC)

Bonding jumpers for cable tray bonding

Types of bonding jumpers

- Insulated bonding jumpers

- Bare bonding jumpers

- Braided bonding jumpers

It is not necessary to use bonding jumpers at standard splice plates because its bolted connections provide adequate bonding .

It is important to install two bonding jumpers from both side rails of the cable tray section to the ground bus at switchgear or MCC .

Installation of cable trays between electrical panels inside buildings

Cable tray clearance requirements

- the cable trays shall be installed over all piping works in the building (such as plumbing pipes).

- there must be a minimum distance of 2 inches (50 mm) between the cable tray and the vertical wall ,also the other side of the cable tray should have a minimum clearance of 12 inches (300 mm) to provide easy access to the cables installed on the tray for inspection or future modifications.

- cable trays installed under raised floor : the minimum clearance between the top of the tray and the bottom of the floor tiles or floor system stringers (whichever are lower in elevation) is 3/4-inch (19 mm) .

- The distance between any two cable trays in the same plane shall not be less than 4 inches (100 mm)